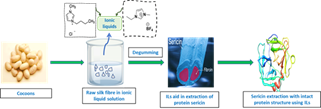

Indian researchers have identified four different types of ILs that could prove effective in extracting silk proteins from raw fibres

Researchers have found an environmentally friendly approach that could eliminate the use of toxic chemicals in silk processing. Traditionally, toxic chemicals such as sodium carbonate, sodium hydroxide, sulfuric acid and lithium bromide are used to extract silk proteins, fibroin and sericin from various types of raw silk fibres, which is a crucial part of the process of making silk from cocoons.

A team from the Institute of Advanced Study in Science and Technology (IASST) Guwahati, an autonomous institute of the Department of Science and Technology, has identified ionic liquids (ILs) that could provide a sustainable alternative to toxic chemicals currently used during the silk protein extraction process.

The team led by Dr. Kamachi Sankaranarayanan has identified four different types of ILs that may prove effective in extracting silk proteins from raw fibres. This new research, published in Chemistry Select by Wiley Publishing, has potential for use in sericin extraction from both mulberry (Bombyx mori) and non-mulberry silks, such as muga (Antheraea assamensis) and eri (Phyllosamia ricini), native to Northeast India.

The researchers explored six different ILs and found that some of them proved particularly effective at removing sericin without damaging the silk protein structure. Those showing the highest efficacy included 1-butyl-3-methylimidazolium chloride (BMIM.CI), 1-ethyl-3-methylimidazolium tetrafluoroborate (EMIM.BF-4) and tetraethylammonium bromide (TEAB). TEAB is presumed to be highly effective due to its ability to destabilize the sericin protein.

The research is of great significance for the silk industry as it not only provides a more environmentally friendly alternative to traditional chemical methods, but it also paves the way for efficient sericin extraction from non-mulberry silks, potentially leading to new applications for these unique fibres.

This is the first example of using ILs for sericin extraction from non-mulberry silk, highlighting the potential of this new approach for a more sustainable and diverse silk industry.