Thin, Micropower Batteries: Growing Interest as Sustainable Solutions

Author: Daniel Parr, Technology Analyst at IDTechEx

Sustainability is a growing concern for OEMs of both consumer-facing and industry-facing products. Incumbent energy storage solutions have come under fire due to unsustainable extraction, manufacturing, and disposal. IDTechEx has seen increasing interest in sustainable alternatives to traditional lithium-ion and primary technologies, including in micro-power applications where thin batteries might be used. The sheer volume of batteries needed in the modern world is enormous. Globally, battery needs have reached multi TWh levels (over 2.4 TWh in 2023, according to the International Energy Agency), with billions of lithium-ion units sold yearly. More than 90% of these batteries end up in landfills. IDTechEx’s report, “Flexible Batteries Market 2025-2035: Technologies, Forecasts, and Players”, includes details on thin, flexible batteries for micro-power applications, and the gradual move towards sustainable alternatives.

Lithium is the primary material used in modern battery technologies. However, it is dependent on lithium extraction. The largest commercial source of lithium is extraction from underground reservoirs (known as salars due to the natural saline solution they contain), which has a relatively low environmental impact. However, lithium mines are a major secondary source. Lithium mines are not currently sustainable, as they contribute to water depletion and habitat destruction.

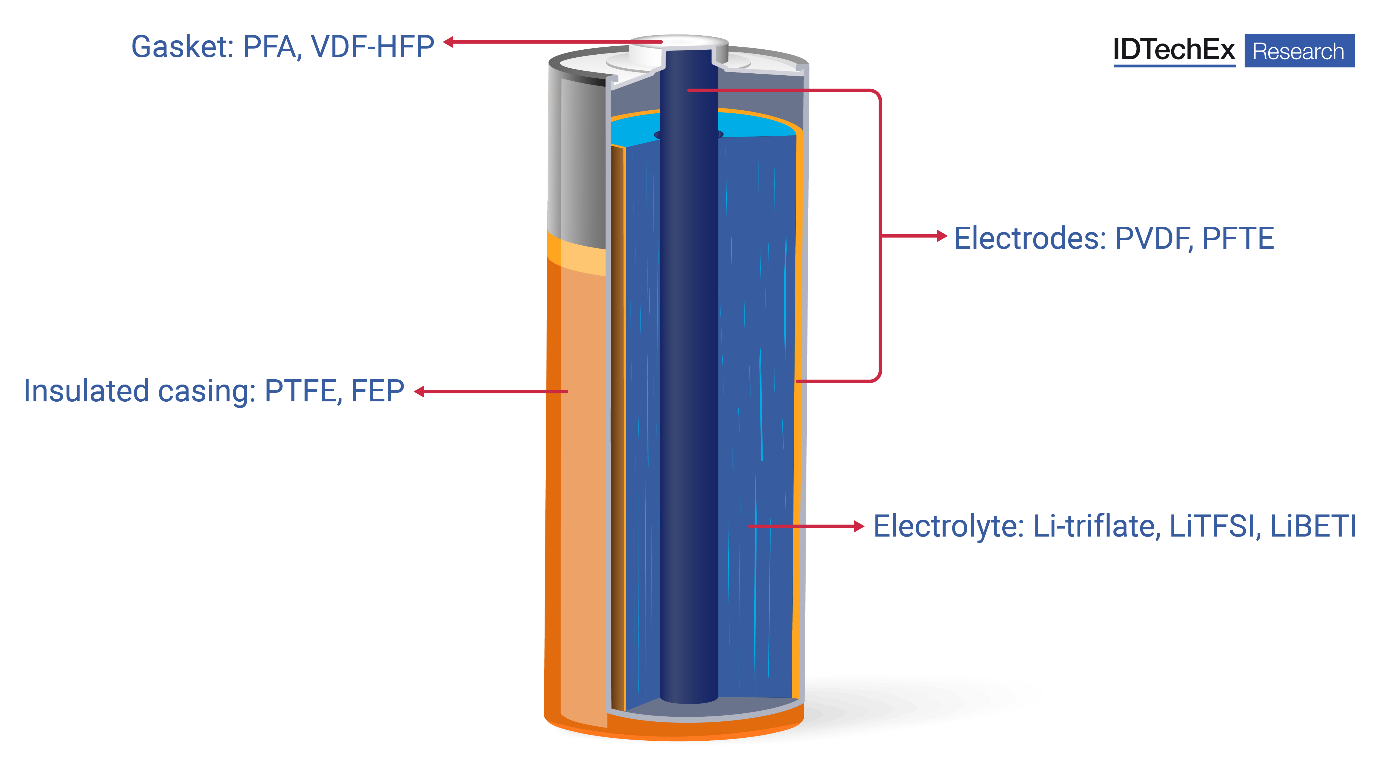

PFAS, or Per- and polyfluoroalkyl substances, are used in multiple stages of battery construction. Firstly, PFAS are used in cathode binders, to attach active material to the electrode and connect current collector to electrode. Specifically, PTFE and PVDF are used in rechargeable and non-rechargeable lithium batteries, as well as several other battery chemistries. PFAS are well-suited to this use as they have good adhesive and dispersive properties. Some lithium-ion batteries also use PFAS in liquid electrolytes, e.g., Li-triflate, LiTFSI, and LiBETI. Depending on the battery, PFAS may also be used in separator coatings and membranes. They could serve as binders in ceramic separator coatings, for example. Generally, these PFAS have low environmental impact and are non-toxic. However, as PFAS have come under increasing interest from governmental bodies, they may see increasing regulation in the future, especially in Europe, where new regulations are expected to be introduced and phased in by 2025. The exact breadth of these new regulations has yet to be determined, which is a major motivator for innovative new methods of battery production.

Illustration of some battery components in which PFAS substances may be used. Source: IDTechEx

As a result of these factors, many players have shown interest in more sustainable materials and manufacturing methods. IDTechEx looked specifically at companies in the thin-film and micro-power space in the report, “Flexible Batteries Market 2025-2035: Technologies, Forecasts, and Players”. Two general approaches can be gleaned from this analysis. First, the development of new manufacturing methods and binder materials for traditional lithium chemistries. Second, the development of new chemistries that replace the need for lithium and, in some cases, remove the need for PFAS-based binders.

The first approach includes the development of dry curing and energy-curing technologies. Ateios is an example of a company that utilizes this type of method. Ateios’ RaicureTM technology involves an energy-curing process for battery electrodes which doesn’t require the use of PFAS. The technology was originally pioneered by Oak Ridge National Laboratory. Ateios combines energy-curable polymers with battery powder to make its electrodes. During the mixing process, the binder is inserted in fragments which helps improve mixing and dispersion. After being coated onto the foil, the film is exposed to the platform process that converts the polymer fragments into an interconnected network that makes the electrode more robust. The use of fragmented binders in the mixing process eliminates the need for solvents.

The second approach includes lithium-free chemistries. Of these, printed zinc-carbon and silver-zinc are most significant in the thin, micro-power battery space. Zinc is more abundant than lithium, has a lower cost to extract, and is considered environmentally friendly. Zinc is extracted from abundant zinc concentrates, generally zinc sulfide. This sulfide is then oxidized to produce zinc oxide, which is leached to form sulfate; the sulfate is purified, and finally, the zinc metal is extracted through electrolysis. Printed zinc-carbon and silver-zinc are valued for their thinness and flexibility and are used for IoT and logistics purposes, especially smart labels. Key players include Zinergy and CCL Design. Their main competition is in coin cells, the majority of which are lithium-based, though some zinc-based chemistries (zinc-air) are also applied. Differentiation through sustainability is increasingly relevant in this application space, especially in Europe.

Another example is the development of a fuel-cell alternative to traditional batteries. BeFC is a French company developing bio-enzymatic fuel cells to replace thin batteries in micro-power applications. The fuel cells are printed on paper and use biocatalytic reactions with glucose to generate power. They are formed from organic materials, which makes them relatively sustainable. The cells are designed to be easily disposable and single-use. The fuel cell is used in the same way as a battery, though a catalyst is required to begin energy generation, which takes two general forms: external stimuli (e.g., biological or environmental) such as sweat, urine, blood and saliva, which may be used in medical or cosmetic use-cases, or rain or river water for remote sensing applications; and artificial stimuli, i.e. the company’s patented blister reservoir, which can be ruptured for activation, similar to a mechanical on-switch. The company is targeting applications in IoT, skin patches, and smart labels, especially use cases where non-toxicity and easy disposability are relevant.

As concern rises over battery material extraction and manufacturing processes, and as regulations continue to loom on the horizon, battery suppliers that can offer sustainable alternatives to traditional technologies will see increasing interest, so long as they can maintain functionality. IDTechEx examines the thin, micro-power battery space in the report “Flexible Batteries Market 2025-2035: Technologies, Forecasts, and Players”, including a discussion of differentiation through sustainability.

To find out more about this IDTechEx report, including downloadable sample pages, please visit www.IDTechEx.com/Flex.

For the full portfolio of energy storage and batteries market research available from IDTechEx, please see www.IDTechEx.com/Research/ES.