Thermal filler materials make up a large portion of the formulation for thermal interface materials, and each has its own benefits and disadvantages, including conductivity, cost, and mechanical properties. IDTechEx's latest report, “Thermal Interface Materials 2024-2034: Technologies, Markets, and Forecasts“, explores the many types of thermal fillers and the wide array of applications for thermal interface materials (TIMs).

Commonly used thermal fillers for relatively low thermal conductivity

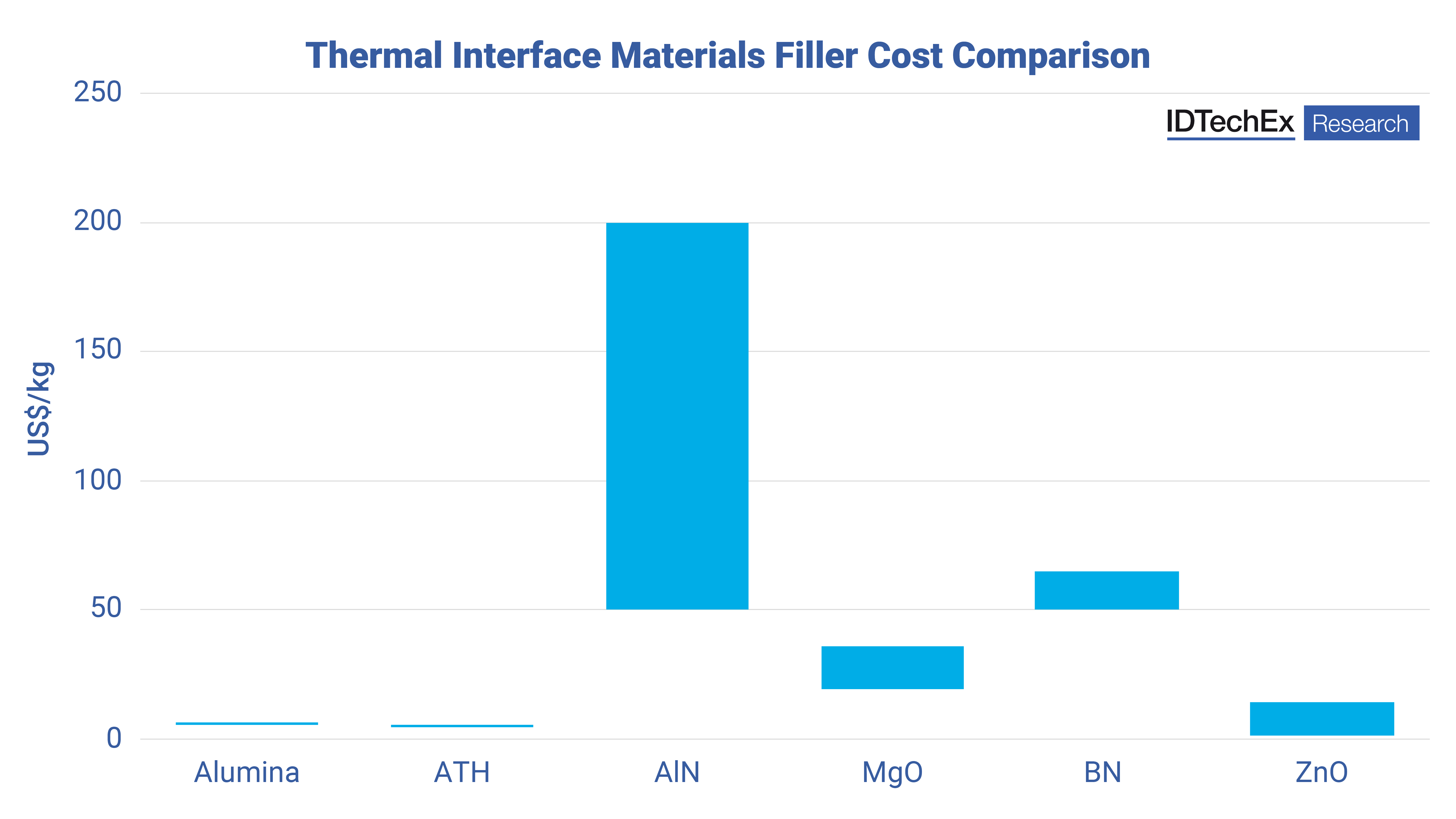

Alumina fillers have low electrical conductivity whilst having a very high melting point of above 2000 degrees Celsius and being chemically inert. They are, therefore, a suitable option for electrically sensitive applications. In addition to the properties mentioned above, alumina fillers have relatively low costs; for instance, spherical alumina fillers cost around US$6/kg, depending on the volume and suppliers. Thanks to their cost-effectiveness, they are the most widely used fillers for TIMs, particularly for electric vehicle batteries.

Thermal interface materials filler cost comparison. Source: IDTechEx

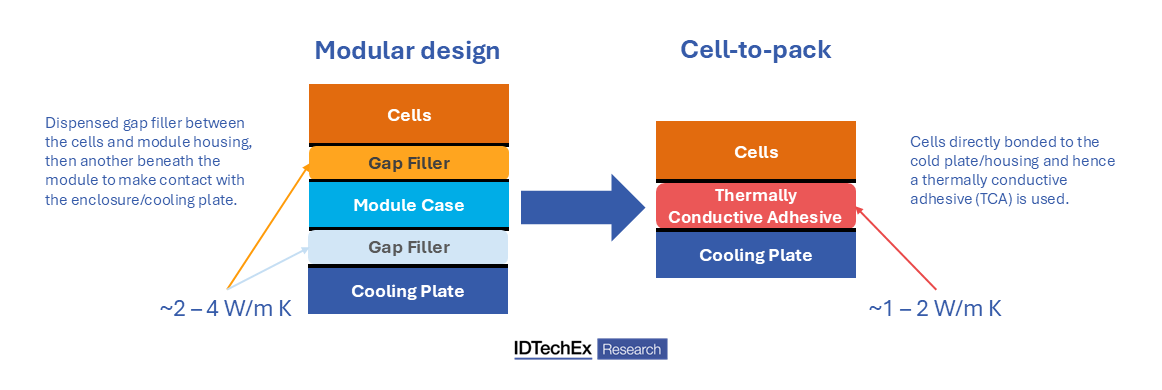

Within EV batteries, a megatrend is the transition from modular battery configuration to cell-to-pack battery architecture, which lowers the thermal conductivity requirement. This transition leads to potential opportunities for aluminum hydroxide (ATH). Despite the lower thermal conductivity, ATH can be sourced at a lower cost, making it an ideal option for the cost-sensitive automotive industry. It also has flame retardancy and fire protection qualities, which could be favorable for EV applications where there may be potential fire risks.

EV battery configuration change from modular design to cell-to-pack design. Source: IDTechEx

Advanced thermal fillers with high thermal conductivity

Aluminium nitride and graphene, on the other hand, both have very high thermal conductivity but come with high costs, meaning their uses are more tailored for high-end applications. Magnesium oxide is another option for high thermal conductivity and is both nontoxic and inexpensive, though it is not widely used and requires specific treatments, as the raw compound cannot be used directly as a filler material.

Mostly used for additives rather than primary fillers, boron nitride (BN) also has high thermal conductivity, is electrically insulating, nontoxic and possesses excellent chemical and thermal stability. However, BN fillers are significantly more expensive. According to IDTechEx's research, the costs of BN fillers can be over 10 times higher than alumina fillers.

Data center applications

High power-consuming components will be the main usage for advanced thermal interface materials, due to components that produce heat, including servers, switches, and power supplies. Within data center components, servers are the main users of thermal interface materials as a result of their large unit numbers, large-sized processors, and chipsets. With the increasing demand for cloud computing, AI and high-performance computing, as well as the growing thermal design power of key components such as GPUs and CPUs, the need for these advanced TIMs for servers will continue to increase, providing a great demand opportunity for the TIM sector.

For electric vehicle battery applications, alumina is expected to remain dominant. Although fillers such as boron nitride have a much higher thermal conductivity and may be preferable, it is much more expensive, meaning adoption will likely happen for high-end applications.

IDTechEx explores many other applications for thermal interface materials including electric vehicles, power electronics, ADAS, 5G. and EMI shielding in their report, “Thermal Interface Materials 2024-2034: Technologies, Markets, and Forecasts“. Downloadable sample pages are available for this report.

For the full portfolio of market research available from IDTechEx, please see: